LNG ( Liquid Natural Gas ) Fuel Tanks for Ship

BTCE has a professional Marine tank manufacturing team, which can carry out the overall design of LNG fuel tanks for ship, including the design of Marine tank body, temperature field analysis and calculation, TCS gas supply system pipeline low temperature stress analysis, strength fatigue calculation, etc. Company headquarters production base can design and manufacture of 1 ~ 300 m³ marine tank product series, nearly port cooperation factory in Tianjin and can manufacture 300 ~ 5000 m³LNG fuel tanks for ship.

| Model | Design pressure | Dimensions(exclude TCS) | Weight(kg) | Type |

| HTS-3CM-12 | 1.2 | 3500×1600×1700mm | 5600 kg | law-enforcement vessel |

| HTS-5CM-12 | 1.2 | 3700×2000×2300mm | 6700 kg | Tugboat |

| HTS-10CM-10 | 1.0 | 4300×2400×2650mm | 9050 kg | Sand dredger |

| HTS-20CM-10 | 1.0 | 7500×2400×2650mm | 12000 kg | Sand dredger |

| HTS-25CM-10 | 0.9 | 6000×3100×3200mm | 19800 kg | Tugboat |

| HTS-30CM-10 | 1.0 | 9300×2600×2900mm | 14200 kg | Steel rolling boat |

| HTS-55CM-10 | 1.0 | 7900×3900×4150mm | 30000 kg | Tugboat |

| HTS-100CM-10 | 1.0 | 17600×3500×3700mm | 38000 kg | Bunkering barge |

| HTS-162CM-5 | 0.5 | 13300×4700×4970mm | 60000 kg | Chemical Oil Tanker |

| HTS-170CM-10 | 1.0 | 17000×4300×4550mm | 80000 kg | PSV |

| HTS-180CM-9 | 0.9 | 18700×4100×4350mm | 63000 kg | Bunkering Vessel |

| HTS-228CM-10 | 0.88 | 18000×4700×5080mm | 88350 kg | Bunkering Vessel |

| VTS-50CM-10 | 1.0 | Φ5700×4400 | 40000 | Tugboat |

| CC-20FT-10 | 1.0 | 6058×2438×2591mm | 10000 | Tugboat |

Special design is available for all models on special request. Design and specification are subject to change without prior notice.

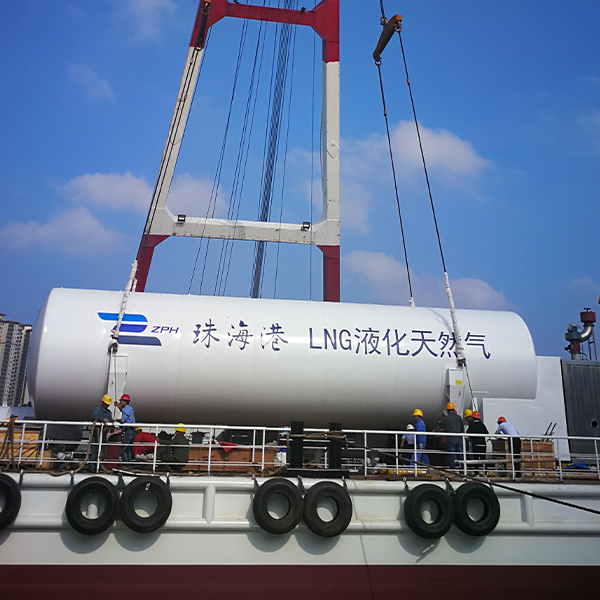

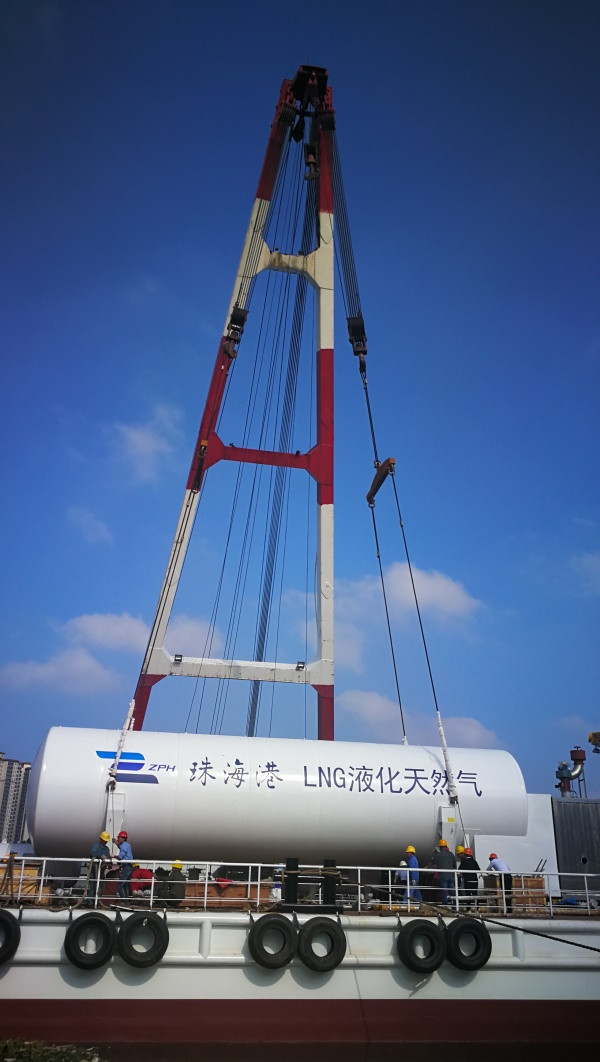

Model HTS-100CM-10 LNG fuel tank in installation

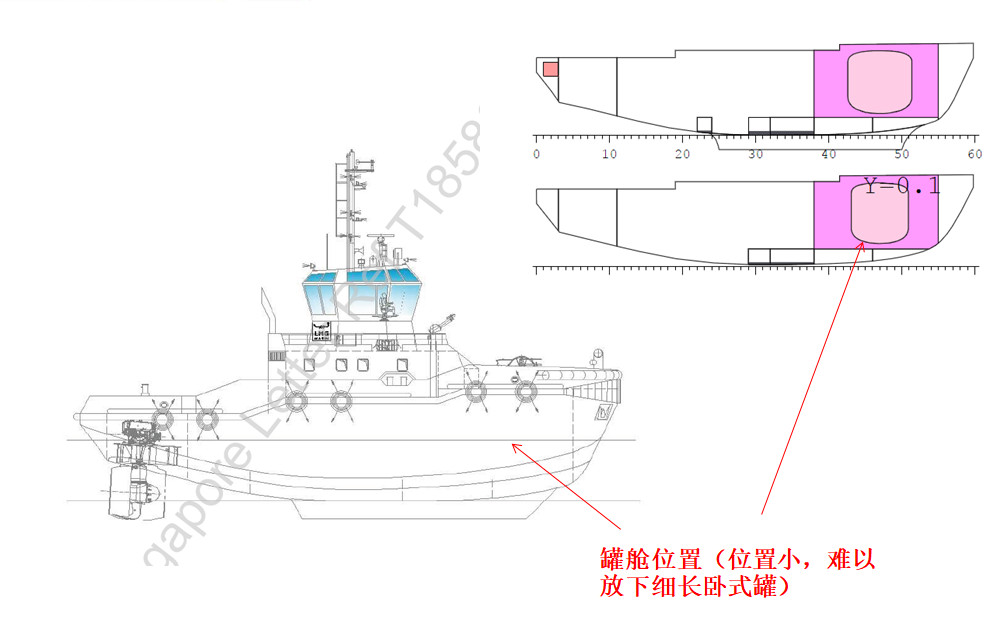

Mobile fuel tank for tug

In 2018, COSL is preparing to put into LNG powered guard ships in Bohai Bay and other areas. It is the first BATCH of LNG fuel platform supply ships built by Chinese ship owners, with a total of 12 units, which will be delivered in early 2020.

At the beginning of 2019, BTCE undertook the project of supporting two 180m3 deck tanks for the 8500 m3 refueling vessel project invested and built by ENN Group, which can hold two different media of LNG/LIN respectively.

In May 2020, the 162m3 fuel tank project of DNV-GL classification Society that BTCE undertook has been successfully delivered. Although the tank volume is small, it has a large diameter and limited total gravity. During the implementation of the project, the design, process, manufacturing and inspection departments fully communicated and cooperated with each other, and finally overcame the difficulties and successfully delivered to the customer. It has been recognized by customers, classification societies and ship owners

The VTS-50CM-10 fuel tank designed and manufactured by BTCE has large diameter and low height, which is better adapted to the narrow space under the main deck of the port tug. The tank adopts top spray precooling, and the top is filled with liquid, which reduces the sharp increase of pressure in the tank during the process of refilling the tank and reduces the emission of NG. The unique internal and external support design structure reduces the heat transfer and increases the maintenance time. The external support of the fuel tank adopts skirt structure, which is connected with the tank base by bolts to ensure that the fuel tank is installed firmly and can better adapt to the ship's transverse trim condition.

Step by step with international maritime organization IMO sulfur limit, LNG as the international shipping industry transition towards zero carbon future fuel, is already the world main choice of ship operators, BTCE as a clean energy equipment industry leader, nearly step to improve the quality of products, Marine products in the international market competitiveness, and to all parts of the world ship with better quality of Marine fuel tank, Contribute to the development of global green shipping.