8 Year Exporter Tank Oxygen - VTN HTN Series Standardized LNG Storage Tanks – BTCE

8 Year Exporter Tank Oxygen - VTN HTN Series Standardized LNG Storage Tanks – BTCE Detail:

BTCE VTN or HTN series LNG storage tanks are designed for LNG (Liquefied Natural Gas), which are vertical (VTN) or horizontal (HTN) storage tank with vacuum perlite or super insulation. The tanks are available with capacities from 5 m³ to 100m³ with maximum allowable working pressure from 8 to17 bar and designed according to Chinese code, AD2000-Merkblatt, EN code, 97/23/EC PED (Pressure Equipment Directive), ASME code, Australia/New Zealand AS1210 etc.

■ VTN /HTN LNG series cryogenic tanks are designed in accordance with all LNG requirements for safe, easy and economical operation. Many of the features have been incorporated in close.

■ Adoption of strain strengthening technology,saving 30% of stainless

■ Proprietary insulation layer support structure design, minimize the heat transfer to reduce the daily evaporation rate, and can withstand severe earthquake load, has won the national patent (patent Number: ZL200820107912.9);

■ The outer container is made of carbon steel, and the places that are easy to damage the paint in lifting, transportation and operation are protected by stainless steel material to ensure the service life and beauty of the paint;

■ All pipeline outlet plates are made of stainless steel, which can prevent the pipeline freezing shell from low temperature brittle crack and damage the paint during use.

■ Optimized perlite filling and insulation material winding process to ensure better insulation effect of insulation layer;

■ The valve operating system is compact and easy to operate and maintain;

■ Valves connected with vacuum are all imported parts to ensure vacuum life and reliability;

■ The outer surface of the tank is sandblasted and sprayed with HEMPEL white epoxy paint for longer life and aesthetics, reduced radiation heat transfer and reduced daily evaporation.

| Model | Gross Volume(m3) | Height or length(m) | Diameter(m) | NER LNG(% capacity/day) | MAWP(MPa) |

| VTN or HTN 5 | 5 | 5 | 2.0 | 0.40 | 0.8~1.7 |

| VTN or HTN10 | 10 | 6.02 | 2.2 | 0.33 | |

| VTN or HTN 20 | 20 | 10.2 | 2.2 | 0.27 | |

| VTN or HTN 30 | 30 | 11 | 2.5 | 0.24 | |

| VTN or HTN 40 | 40 | 9.9 | 3.0 | 0.22 | |

| VTN or HTN 50 | 50 | 11.3 | 0.19 | ||

| VTN or HTN 60 | 60 | 13.2 | 0.19 | ||

| VTN or HTN 80 | 80 | 13.5 | 3.6 | 0.15 | |

| VTN or HTN 100 | 100 | 16.3 | 0.14 |

Beijing Tianhai Cryogenic Equipment Co., Ltd. is the earliest LNG storage tank manufacturer in China, and has close cooperation with the world’s largest LNG integrated equipment manufacturer, Houpu Clean Energy Co., Ltd. and Chongqing Naide Energy Equipment Integration Co., LTD. Our equipment is widely used in large domestic energy companies, such as PETROCHINA, Sinopec, China Gas, etc., followed by integrators to expand foreign business, our products are used in the European Union, Southeast Asian countries.

The advantages of using LNG products of our company include:

1. Produce high quality pearlite by ourselves. In order to ensure that the storage tank has the highest level of thermal insulation effect, the key filling material in the vacuum layer of the storage tank pearlized sand is self-produced and supplied, and the professional puffing furnace is imported from the United States. In the market circulation, the price of pearlite is usually calculated according to the volume. In order to obtain higher profits, some pearlite manufacturers expand the pearlite to the maximum, resulting in a sharp decline in the insulation performance of pearlite. Our company uses professional equipment and technology homemade pearlite, strictly control the pearlite expansion ratio, to ensure the optimum pearlite expansion coefficient and application effect. From the root to ensure the excellent and stable thermal insulation performance of our company’s storage tank, the daily evaporation rate is far lower than the national standard requirements (generally less than 0.2%)。In addition, users can reduce unnecessary pressurization emissions in the process of use and obtain better economic benefits.

2. Support structure between internal and external containers with patented technology. The support scheme between the inside and outside of the storage tank is also our patented technology. Through the special metal structure support with the characteristics of flat, narrow and long, the heat transfer effect between internal and external containers is well reduced, and it also has the characteristics of stable support and long metal fatigue life.

3. HEMPEL paint imported from Denmark. Tank surface paint quality is excellent and through advanced painting process to ensure smooth tank surface. Storage tanks can be durable, colorfast and high reflectivity to light. With the best quality of paint and the best workmanship to ensure the maximum reduction of external heat radiation on the tank.

4. Optimized pipeline layout and design. The structure design of inlet and outlet pipeline is reasonable and has been tested for long-term application, which greatly reduces the electrostatic generation in the process of LNG liquid reinstallation. And in the process of liquid intake, it can play a role of cooling and reducing pressure in the gas phase space of storage tank. It greatly reduces the flow resistance during liquid extraction and avoids the formation of liquid whirlpool during rapid liquid extraction. Reasonable outlet layout, avoid two outlets at the same time when the liquid deflection phenomenon.

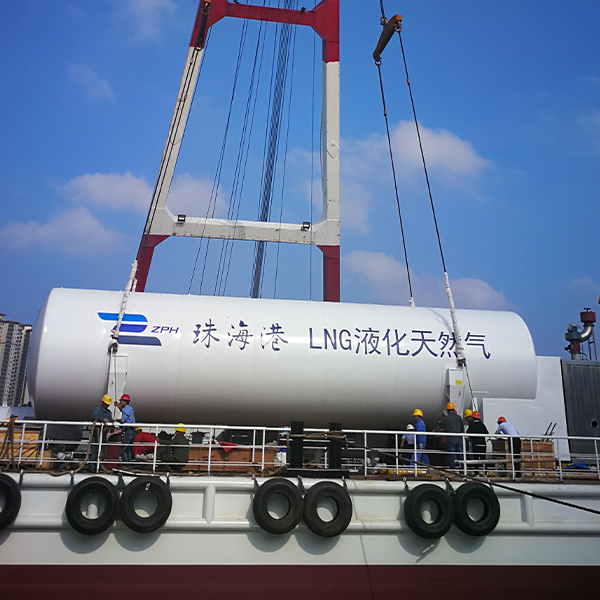

LNG Peak regulation station site

Product detail pictures:

Related Product Guide:

As a result of ours specialty and service consciousness, our company has won a good reputation among customers all over the world for 8 Year Exporter Tank Oxygen - VTN HTN Series Standardized LNG Storage Tanks – BTCE , The product will supply to all over the world, such as: Malta, Serbia, Liberia, By adhering to the principle of "human oriented, winning by quality", our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.